SPOD offers you a variety of printing methods. Which one is best? That depends on the product material and the characteristics of your unique design.

Sometimes,

the printing technique is automatically selected based on what material the product is made out of.

For example, mugs, caps, or other accessories are often only compatible with

one method of printing.

For other, purely fabric products – like T-shirts, hoodies, or baby bodysuits —you have the choice between two techniques: Digital Direct or Direct to Garment (DTG) printing or Flex and Flock printing.

Digital Direct printing works similarly to a normal inkjet printer: your design is sprayed onto your product with ink.

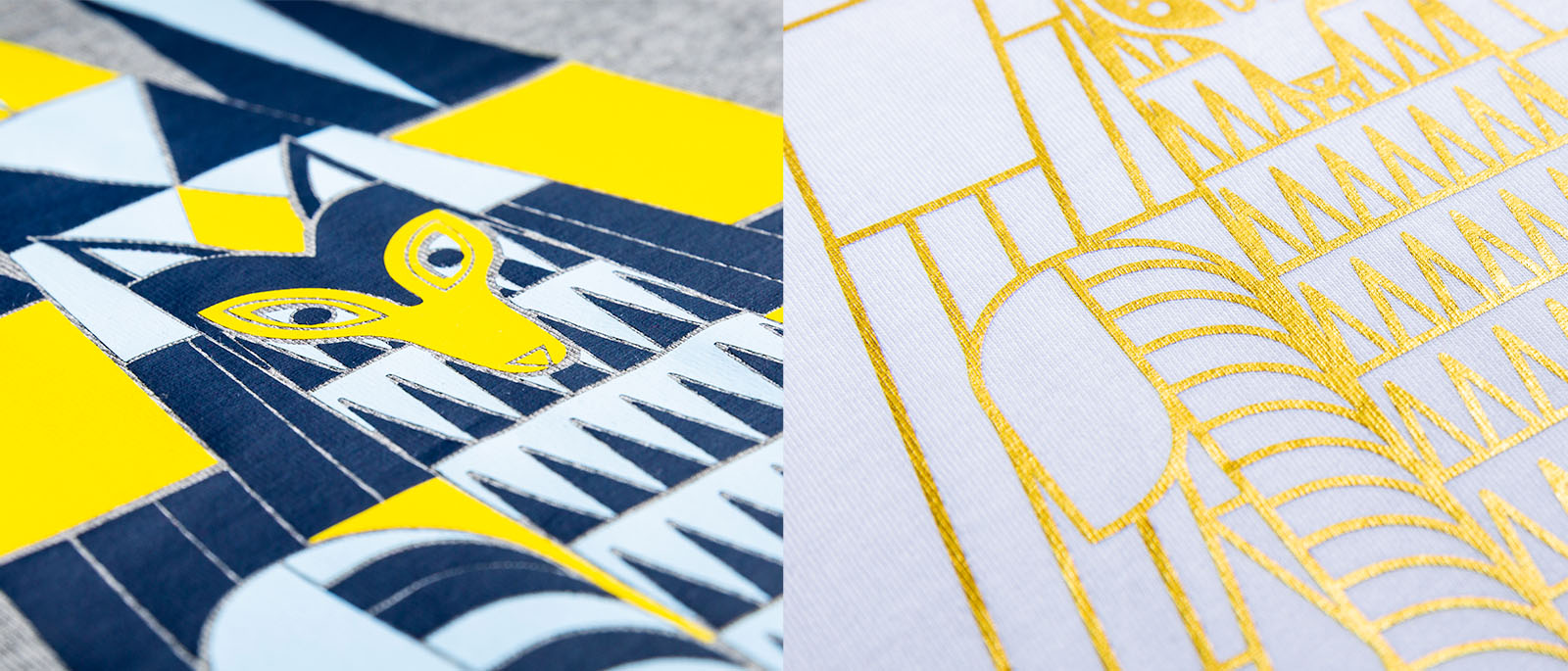

Flex and Flock printing methods work by transferring your design onto the product using a special foil.

Flex

Flex

Flock

Flock

To see the difference for yourself, try ordering samples using each print method so you can compare the look and feel side-by-side.

Bear in mind that with either printing technique, the colors will never be exactly the same as you see on your screen or on a paper printout. This is due to the unique calibration of each computer’s display, as well as product colors. Learn more about color differences between your monitor and a finished product here.

For details on all of SPOD’s printing methods, check out this FAQ.

How do I select my preferred printing method?

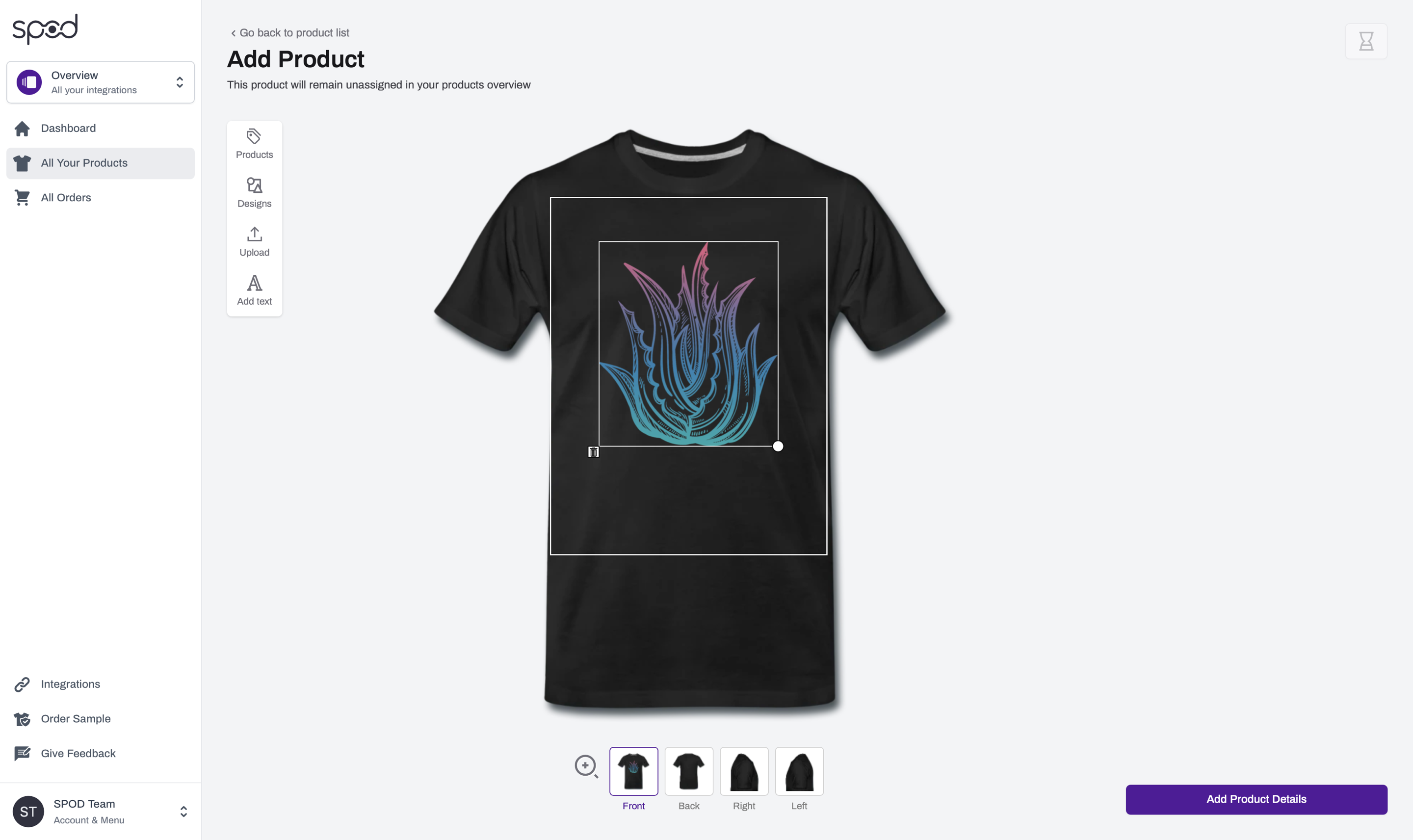

If your product and design allow you to choose your method of printing, you will be able to select this when you upload your design in the Design Tool. Check out this video walkthrough for more details.

SPOD’s Design Tool automatically assesses the product material and your design file type to check whether alternative printing techniques are possible.

Digital Flex and Flock

Digital Flex and Flock

What are the criteria for Digital Direct vs Flex/Flock printing?

Digital Direct DTG is our default printing method. This is because it is flexible and well-suited to all designs.

Flex and Flock have more specific criteria:

- Must be a vector file: svg or ai (Adobe Illustrator)

- Design outlines must be bigger than 1.5 mm

- Design can contain a maximum of 3

colors. The colors must be

available in the Design Tool. Flex foil is available in many different colors, which you can

see listed in the Design Tool. Color gradients or transparencies are not

possible with Flex or Flock.

While you are creating your Flex/Flock product in the Design Tool, you can test out different colors and see what looks best. The vector file format makes it possible to switch colors easily.

Which printing technique should I choose for my design?

We’ve put together a cheat sheet for you to find out which method best suits your design.

If your design features fine lines and small details:

Use DTG. DTG allows for fine details, whereas Flex gives best results with lines thicker than 1.5mm.

If your design features large color blocks:

Use DTG. This is down to breathability: because DTG uses ink, the large areas of color will remain breathable. With Flex methods, large colored areas are created via foil transfer, leaving large portions of the garment impermeable to air.

If your design is text-only:

Use Flex. Flex offers strong contrast and an eye-catching, smooth and glossy finish. This makes slogan or text-based designs stand out even after many washes.

If your design is a photo:

DTG will be used by default. This is because photos feature large blocks of color and many color gradients.

If your design is multicolored:

Use DTG. Flex and Flock printing methods are only compatible with a maximum of 3 colors (1 color if using Special Flex). DTG can produce unlimited colors and gradients.

If your design is an illustration:

Use Flex or DTG. Choose Flex if your illustration is simple or features solid shapes in a maximum of 3 colors. For designs which cover more than 50% of the print area, are more colorful or complex, DTG is the better option.

If you want the same color results on different textile products:

Use Flex or Flock. If you are looking for consistent printing results on a variety of items, the foil used in Flex and Flock printing techniques will give you the desired results. By contrast, DTG can result in slight variations in color due to the combination of the ink and the color and fabric of the product.

If you want glitter or velvet effects:

Use Special Flex and Flock. Please note that these special effects are only available in one color per design.

Special Flex

Special Flex

Which new printing techniques are coming to SPOD in the future?

SPOD is always improving in order to offer our merchants the best printing techniques. We will soon release a new method of Flex and Flock printing using a different, slightly thinner foil. This foil will transfer with less heat and pressure, and offers a better first impression for customers. It is more compatible with synthetic fabrics than our current foil.

Exciting, high-quality methods such as embroidery and screen printing are also in the works!

Let’s get printing!

Choosing the right printing technique for your designs will help your products look their best for your customers. Ready to put your new printing know-how into action? Why not add some new products to your shop and order some samples? Or if you’re new to SPOD and ready to get started, you can register here.

As always, we are happy to help if you have any questions about SPOD or our printing methods. Don’t hesitate to get in touch!