How many new items of clothing did you buy this year? And how many print-on-demand pieces did you sell in your online shop?

The average person in Germany buys 60 items of clothing per year. On a national scale, that’s 5.2 billion items, of which Greenpeace estimates around 2 billion are either never, or rarely worn. Print-on-demand (POD) fights overproduction by only processing items when someone orders them. This approach could revolutionize the textile industry, making it more sustainable. As a SPOD merchant, you are part of the movement towards more sustainable e-commerce.

Let’s have a look at some of the hard facts behind your products: It takes 232 fairly-paid employees at our production facility in Legnica, Poland, to make certain that millions of T-shirts, accessories and jumpers reach our customers in perfect condition. At peak times, up to 430,000 products are printed at our Polish plant each day. In fact, around 2.7 million products were printed and shipped to almost 200 countries last year.

With that amount of items comes great consideration about our carbon footprint. Our organic collection, however, can boast a 20 percent smaller environmental impact that a standard white T-shirt bought in a retail shop. For perspective, an average white T-Shirt can cause 3.7 kilograms of carbon dioxide during its lifespan.

So, organic or standard, how do the products you’re offering with SPOD measure up? How sustainable is print on demand? Let’s have a look at some of the points which make POD a sustainable method:

1. Saving Production Resources

With print on demand, customers can become designers in their own right. For events like bachelor(ette) parties or birthdays, many people design their own garments, putting their heart and soul into creating the perfect item. These kinds of personalized items have a longer life cycle than standard, off-the-shelf products because of their sentimental value. This is obviously a huge advantage for brands such as Spread Group who are moving towards sustainable production of garments. With this high level of individualism, there are very few returns and zero offcuts during production. Anything that is returned has personal designs or logos is recycled and used for insulation, again decreasing wastage.

2. Saving Water with Digital Direct Printing

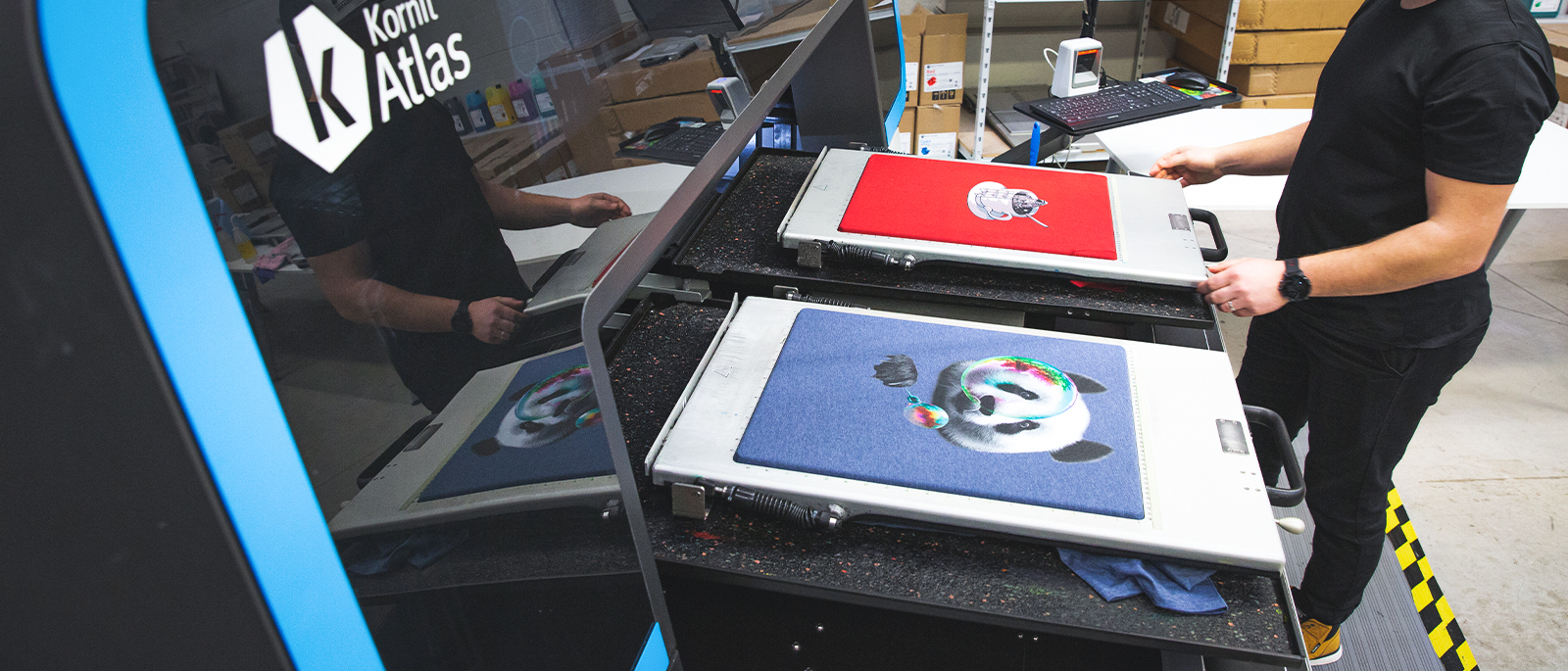

An industry mainstay, the Digital Direct process is regularly used and renowned as being an eco-friendly printing solution. Screen printing, for example, requires far more water than Digital Direct to apply designs onto products. It is partially due to this that Spread Group finishes the majority of our garments in Legnica using Digital Direct. Using both Kornit and Brother printers during the process, we also manage to produce high-quality results with water-saving, sustainable ink. As an added bonus, this ink is vegan and is certified with an OEKO-TEX Eco Passport.

3. Fair Production Conditions

Fair working and production conditions in POD are by default in each company’s Code of Conducts. Taking it a step further, some companies keep up a long-standing relationship with their producers. The Supply Chain Management and Purchasing departments from Spread Group, for example, have met many of our production partners personally on several occasions. These meetings have served as an opportunity to see first-hand the high level of social standards in the production facilities. These meetings add a level of transparency to our partnerships which we value greatly.

4. Transparent supply chains

From extraction and use of raw materials to supply chains, POD also accounts for a high proportion of CO2 emissions. To keep the environmental impact as low as possible, Spread Group’s own collection uses organic cotton grown in Turkey. It is processed locally and is then sent to finishing factories such as the one in Legnica. Spread Group’s assortment also uses sustainable alternatives such as with the brands Stanley & Stella, Neutral and Continental Clothing.

Furthermore, transport routes are also taken into consideration. We have optimized the process to ensure the shortest shipping distance to the end customer. By using these initiatives, our organic collection has the lowest carbon footprint within our entire product portfolio.

5. Low return rates

The national average in Germany is around 12% for online retailers, however Spread Group’s brands managed to achieve a 5% return rate last year. We believe that our high quality print and design is also partially responsible for this. In fact, we reject designs with a pixel count below 1000px so we can always guarantee the best results.

People like to feel good about their purchases, and sustainability is an increasingly important factor in customer decision-making. Be sure to let your customers know that they’re making a greener choice by shopping with you!

We understand that every person and every company must work together on sustainability, and this is only a small part of what we're trying to achieve.

If you like what you've seen here, register today and join us in our mission.